When it comes to DIY household repairs, there’s a special kind of satisfaction that comes from fixing something as fundamental as your kitchen oven. If your oven needs help reaching the correct temperature or if your baked goods are coming out unevenly cooked, the temperature sensor might be the culprit. But fear not—we’re here to guide you through the process, making it easy and manageable, even for non-experts! So, grab your tools and let’s get started on this appliance-saving adventure!

Understanding the Oven Temperature Sensor

An oven’s temperature sensor plays a critical role in ensuring that your cooking attempts are a success. This essential component is responsible for monitoring the temperature inside the oven cavity and relaying vital information to the control board, allowing it to maintain the ideal heat level for your culinary creations. By detecting fluctuations in temperature and transmitting electrical signals to the control board, the sensor enables the oven to make real-time adjustments to its heat output. However, if the temperature sensor experiences a malfunction, it can result in inaccurate temperature readings and ultimately lead to uneven cooking outcomes.

Signs of a Faulty Temperature Sensor

If your oven temperature seems to fluctuate widely, you may experience inconsistent cooking results, which can be frustrating when trying to prepare your favourite dishes. Additionally, if your food takes longer or shorter to cook than the recipe suggests, it could indicate a potential issue with the temperature sensor. Uneven heat distribution may also become evident when the exterior of your baked goods is overdone while the inside remains undercooked, highlighting the importance of a properly functioning sensor. Moreover, if you notice error codes on the oven display related to temperature regulation, this could be a clear signal of a malfunctioning sensor that needs attention. Here’s a quick checklist of signs you need to replace your oven’s temperature sensor:

- Inaccurate Temperature Readings: When the oven heats to 350°F but displays 250°F, your sensor may be the culprit.

- Long Cooking Times: If recipes take longer than usual, your oven’s actual temperature might be off.

- Inconsistent Baking: One side of your oven-baked goods is lighter or darker than the other, indicating uneven temperatures.

- Errors in Self-Cleaning Feature: If your oven doesn’t enter self-cleaning mode due to temperature errors, it could be misreading the sensor.

If you spot these issues, it’s time to replace your oven’s temperature sensor.

Tools and Materials Needed for Replacement

The first step to any DIY project is assembling your materials. For this job, you’ll need:

- The model number of your oven

- A replacement temperature sensor (ensure it is compatible with your oven)

- Needle-nose pliers

- Screwdriver (flathead or Phillips, depending on your oven model)

- A multimeter for testing electrical connections (optional but recommended)

Read More: 7 Tips to Maintain Your Gas Oven and Prevent Leaks

Step-by-Step Guide to Replacing the Oven’s Temperature Sensor

Safety First

Always unplug your oven or turn off the circuit breaker before beginning to work on any electrical components. Also, ensure the oven is cool to the touch before you start.

Access the Sensor

The sensor is typically located at the back of the oven. Most ovens will require you to remove one or more panels within the oven to access the sensor.

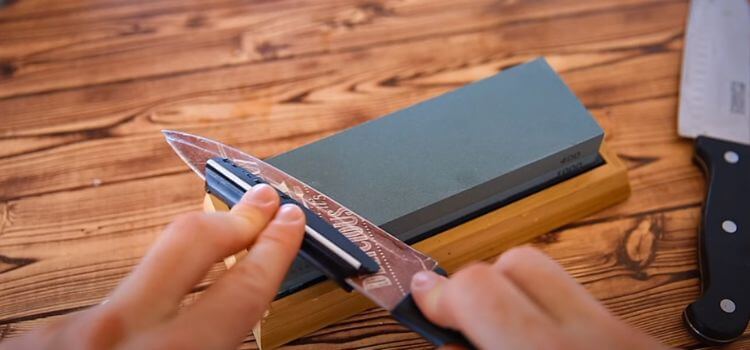

Removing the Old Sensor

Once you’ve located the sensor, you’ll see where it connects to the oven’s wiring. Disconnect the electrical connector (some sensors plug into the oven, while others are wired directly with wire nuts). Then remove any screws holding the sensor in place inside the oven. It should easily slide out from the inside.

Installing the New Sensor

Slide the new sensor through the hole in the back of the oven and screw it into place. Reconnect the electrical wiring according to your oven’s instructions (consult your manual if needed).

Double-Check Before You Reassemble

Switch the power back on, and with the oven door closed, turn the oven on to a low temperature to ensure the sensor warms up. Use a multimeter to check the new sensor’s resistance, comparing it to the manufacturer’s specifications. The multimeter will verify that the sensor is sending the correct data to the oven control board.

Complete the Repair

After you’re satisfied with the replacement, put the oven’s inside back together and test it at different temperatures to make sure it warms up correctly.

Benefits of DIY Replacement

There’s more to gain from tackling this project than simply saving on a service call. Replacing your oven’s temperature sensor yourself can:

- Save Money: The cost of the sensor itself, even if it’s high-quality, is significantly less than a repair technician’s time and labour.

- Boost Confidence: Successfully completing a repair like this can instil confidence in your DIY skills and lead you to tackle more complex home improvement projects.

- Improve Oven Performance: A new temperature sensor can bring your oven back to its original, reliable temperature precision, which is invaluable for home cooks and bakers.

Conclusion

The oven temperature sensor may be small, but its role in the kitchen is enormous. By replacing this essential part yourself, you not only save on costs but also become more knowledgeable about your appliances and how to maintain them over time. Remember, when attempting a DIY repair, the most crucial tool you have is patience. Take your time, follow each step carefully, and you may find that your oven is better than before – all thanks to your newfound expertise in oven technology! Happy DIYing and even happier (and tastier) baking.

FAQs

Symptoms of bad oven temperature sensor

Symptoms of a bad oven temperature sensor can lead to various issues affecting the cooking performance. These symptoms include longer cooking durations, oven overheating, excessive temperature fluctuations during cooking, uneven cooking where some parts are burned while others remain raw, and meals cooking unevenly. Additionally, if the oven isn’t heating to the set baking temperature or if it’s too hot or not hot enough, it could indicate a malfunctioning oven temperature sensor. Testing the oven thermostat with an oven thermometer can help diagnose these issues accurately.

How do I know if my oven temperature sensor is broken?

When an oven temperature sensor is broken, it can result in inaccurate temperature readings that impact cooking performance. Common signs of a faulty oven temperature sensor include longer cooking times, overheating of the oven, inconsistent temperature during cooking, unevenly cooked meals with some parts burnt and others undercooked, and the oven not reaching the desired baking temperature